Spray Drying in the Pharmaceutical Industry

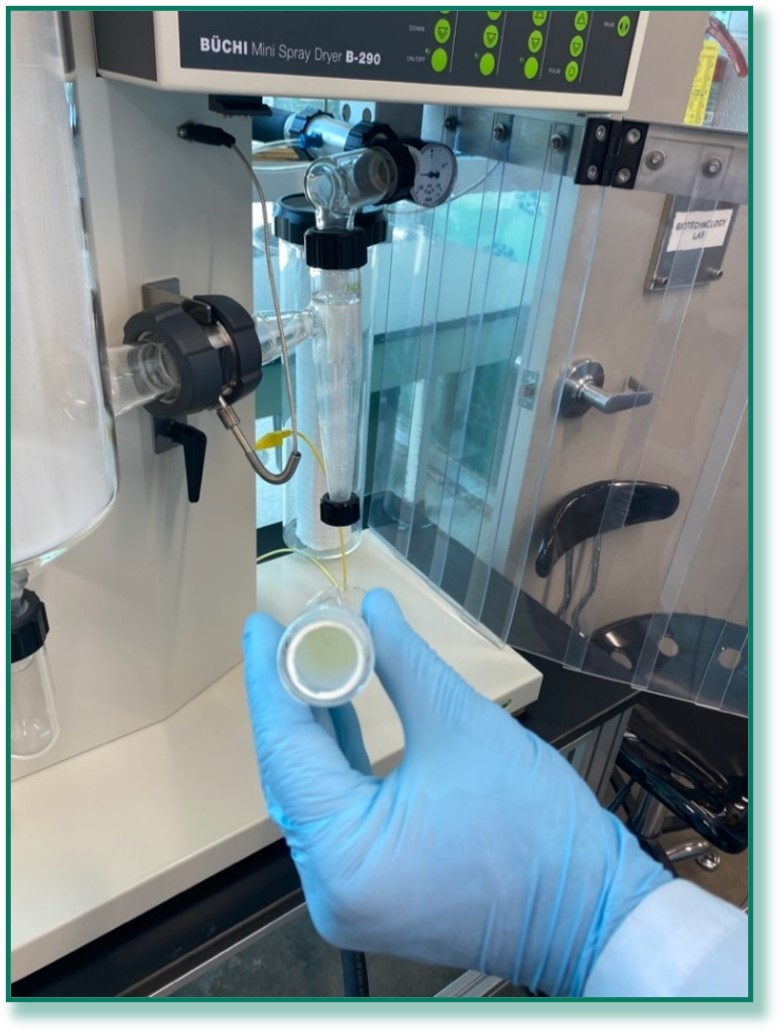

The Oak Crest Institute of Science is making use of high efficiency spray drying techniques common in the pharmaceutical industry to create high quality powders from liquid samples (1). Spray drying uses an atomizing spray nozzle to control the size of particles that are to be dried. As hot air drives water from samples, evaporative cooling prevents overheating of the particles, resulting in a pure powder form of the original liquid sample. This drying method is advantageous in a variety of industries due to its single step process and high powder purity and yields. Here, we demonstrate the effectiveness of this technique by spray drying lactose, a common component in pharmaceutical applications, such as the formulation of tablets and capsules (2).

Buchi Mini Spray Dryer B-290 at Oak Crest.

Collection vial with lactose powder after spray drying.

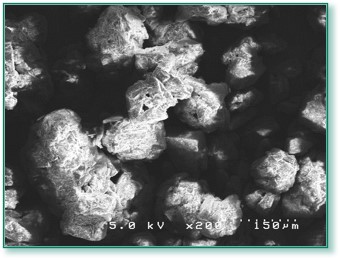

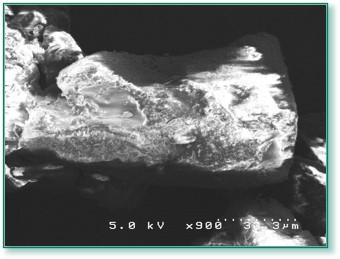

SEM of lactose powder before spray drying at 200x magnification.

SEM of lactose powder before spray drying at 900x magnification.

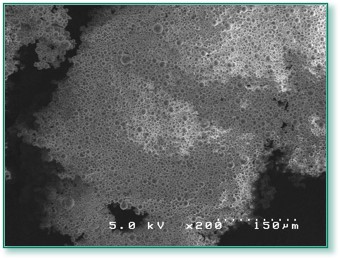

SEM of lactose powder after spray drying at 200x magnification.

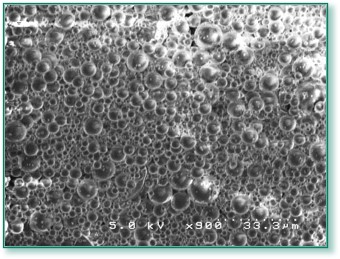

SEM of lactose powder after spray drying at 900x magnification.